Main Features

ECS-700 brings your operators a friendly and efficient operating environment that keeps every operator clearly informed, and easy to control the process. Typically, the system can be called in project as DCS, FCS, PCS, IACS, PDCS, etc.

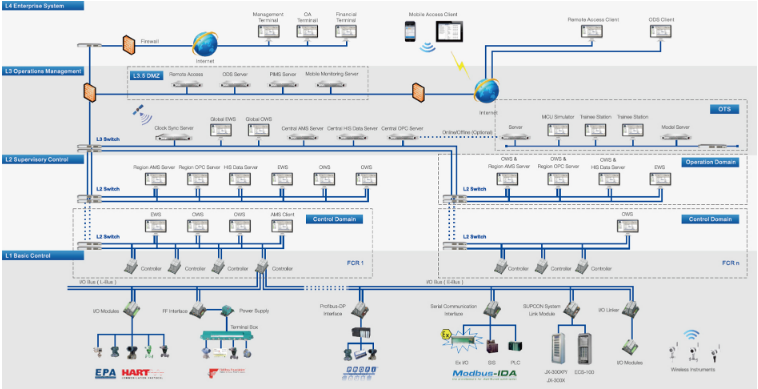

As the core digital automation platform of a modern plant, ECS-700 captures plant-wide data in real time via various standard interfaces, such as OPC, MODBUS, HART, FF and PROFIBUS, and delivers the right data to the right person on right time.

By implementing Control Domain and Operation Domain strategy, ECS-700 supports flexible expansion of your plant up to 65,000 I/Os for each control domain and supports up to maximum 60 control domains. By adopting ECS-700, you can expand your plant scale as you wish.

By implementing Control Domain and Operation Domain strategy, ECS-700 supports flexible expansion of your plant up to 65,000 I/Os for each control domain and supports up to maximum 60 control domains. By adopting ECS-700, you can expand your plant scale as you wish.

ECS-700 is a highly reliable control system. The stable operation throughout the whole process is completely free from the failure of any single component. Designed in compliance with European Community EMC Directive II, and special anti-corrosion coating in compliance with ISA71.04 standard G3. Also, the system passed CE EMC and CE LVD certificates, as well as the highest level (Level II) test of Achilles, one of the most critical certificates for cyber security. See more

An architecture covering a variety of plant sizes & industries

ECS-700 has an architecture consisting of HMI, field control stations, and a control network. These three basic components provide flexible scalability from small scale to large and complex facilities.

Intelligent solutions to improve

your plant performance

Industry is considered a driver for innovation, growth, and social stability. At the same time,

however, competition is growing more intense. Only those who can make do with less energy and fewer

resources will be able to cope with the growing cost pressure.

These challenges can be overcome. As a partner of customer, SUPCON developed a variety of automation

solutions to assist your plant performance; these solutions cover the lifecycle of your plant,

such as SAMS, FF, SCSS, integrated platform, OTS, MES, APC, Batch, etc.

Users can use the device DTM to easily modify parameter and execute advanced diagnosis. Device DTM provides more advanced diagnosis functions combined with graph and is more illustrative.

- Output failure

- Local override

- Loop in manual

- Device out of service reports

- Input failure/process variable has bad status

- Excessive loop variability

- Organization of the security committee

- Identification of the assets

- Continuous monitoring and revision

- Identification and evaluation of the threats

- Identification and evaluation of the vulnerability

- Design and implementation of the security measures

- Enhanced cyber security design

- Integrated engineering tools

- No single point of failure design

- Intuitive and integrated operation platform

- Integrated asset management platform

- EEMUA guidelines oriented alarm management platform

WhatsApp us

WhatsApp us